UR Machine Tending

Danger: Before connecting IO, turn the robot off and disconnect the power. Waita minute for any charge to dissipate. Or risk the unfortunate fate of being human toast! 🍞

Warning: If you wear out the IO connections by abusing them, shame on you! 🔔 shame! 🔔 shame!

You can store your installation as you store a program. Changes to the default installation will be deleted.

Theme

- External E-stop

- Digital IO for program flow

- Relative waypoints

- Built-in functions

- Templates

- Machine tending

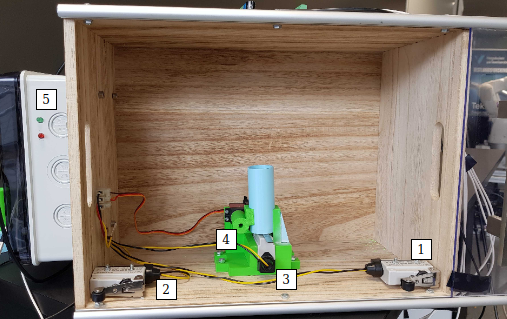

Equipment

-

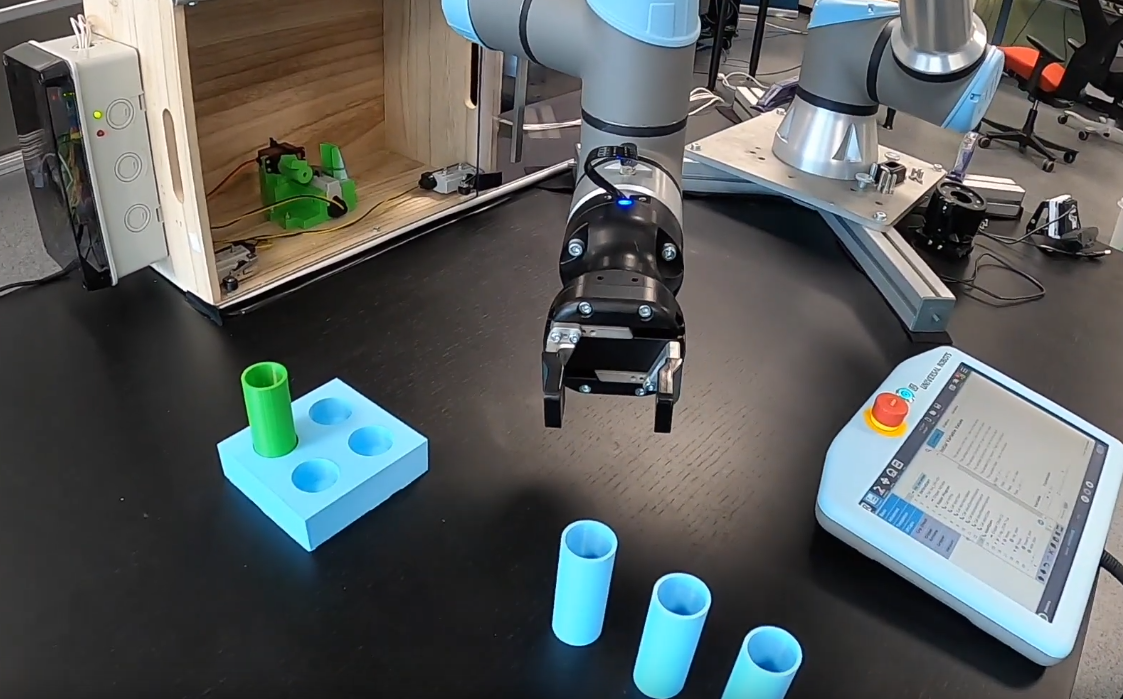

UR5e robot with PolyScope.

-

Robotiq 2-Finger Adaptive Robot Gripper / Hand-E Gripper

-

Lab station with

- E-stop, box with red button and 2 sets of wiring

- Workpiece holder

- Stack of workpieces

- Big box with sliding door.

Before the lab

1.Very important: Complete the Universal Robots Academy

- Setting up a tool

- Safety settings

- Program Flow

- Feature Coordinates

2.Try to get together in a group of 2-4 people.

3.Top tip for preparing: Use the offline simulator from UR. For the ambitious; do all your programming in the simulator, bring your saved program to the lab, bridge the simulation gap, success! 🌈 Or just wait for the lab to do it directly on the real robot…

Report

There is no need to hand in a report after this lab. Signed attendance will suffice as approved lab exercise.

Tasks

Connect and test the E-stop

The UR cabinet is ready for the E-stop to be connected using a screwdriver. The E-stop IO's in the cabinet are all connected by short-wires, giving the E-stop inputs high signals at all times. If, for any reason, this voltage goes away, an emergency stop is triggered just as when using the E-stop on the pendant.

The new E-stop contains 2 NC switches. If the red button is pressed, the switches are opened, breaking the circuits.

- Shutdown the robot

- Disconnect power

- Wait a minute

- Connect the new E-stop

- Fire up the robot again and verify that all E-stops work

Connect Control box digital IO's, test IO's

You will connect a total of 4 digital inputs to the UR, from the controlbox.

- Shutdown the robot

- Disconnect power

- Wait a minute

- Make the necessary connections to connect buttons and indicators todigital I/O.

- Fire up the robot again

- Test and name the inputs

Elements of the Work Station

- Door_open sensor

- Door_close sensor

- Workpiece_sensor

- Clamp servo

- Ready_LED and busy_LED

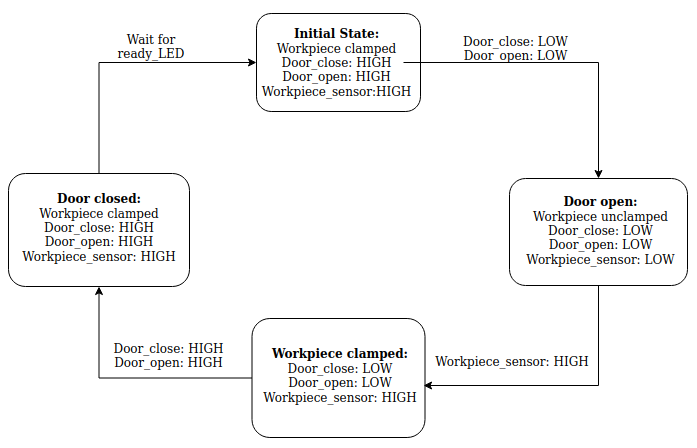

Finite-State Sequence of the Machine Tending Box

Set the machine to its initial state when starting up.

Make a program to open the machine door

Make a program to open the machine door. This might sound easier than it is. Feel free to fasten the box. Consider using force control.

Make a program to close the machine door

Make a program to close the machine door. Same as above, but closed.

Make a program to pick up a workpiece

Make a program to pick a workpiece. There are several ways to do this. Consider the following suggestion as a starting point:

- Move to a waypoint above the workpiece.

- Lower slowly relative to the waypoint above.

- Close gripper, until workpiece is detected.

- Relative move up 1 cm.

- Move to position.

The direction option can be used to detect an object on contact and perform an action. Also, have a look at stack/de-stack options on the UR5e.

It is also possible to detect the force applied to the gripper on contact, with pre-built functions. Have a look at them!

Tip: my_variable = get_actual_tcp_pose() and add 0.01meters to the Z index, then MoveL to this variableposition.

Make a program to place a workpiece in the work station

Make a program to place a workpiece in the work station. Try to be as accurate as possible when placing the workpiece!

Make a program to place workpieces in a grid

Make a program to place the workpieces in a grid. There are several ways to do this. Consider the following suggestions as a starting point:

- Make a waypoint at a corner of your grid.

- Make a counter, row_num.

- Increment counter each time a box is picked from machine.

- Offset placement waypoints by using row_num.

- Add col_num to the mix.

Also, take a look at palletize/de-palletize options on the UR5e for thebuilt-in template.

Combine everything to a complete machine tending program

Using the above programs as subprograms or copy/paste source, make a program to open the door, fetch the workpiece, place them in a grid, feed the machine a new workpiece and close the door. Wait until it’s finished. And repeat. One workpiece at a time.

Voilà! Kick your feet up and let the robot do all the work!

Questions

- The E-stop has 2 NC switches. Why?

- How many tasks did you complete? What kept you from completingeverything?

- If the robot or the "CNC" changed location, how would you updatethe program?

- What are the pros and cons between cobots and industrial robots?

- Discuss how cobots can be applied to enhance workflow for a company,or in everyday life.

- Does the configuration of the robot affect the applied force whenopening/closing the door?

- Did you remember to have fun?